From prototypes to end-use plastic or metal parts with Performance and Speed to meet your needs on-demand

Looking for more than a desktop 3D printer can provide? Need an alternative to your in-house capabilities? Our industrial 3D printing service ensures accuracy and repeatability so you get highly precise parts — every time. At Parts On Demand, additive manufacturing is designed for functional prototypes, complex designs, and production components in as fast as 1 day.

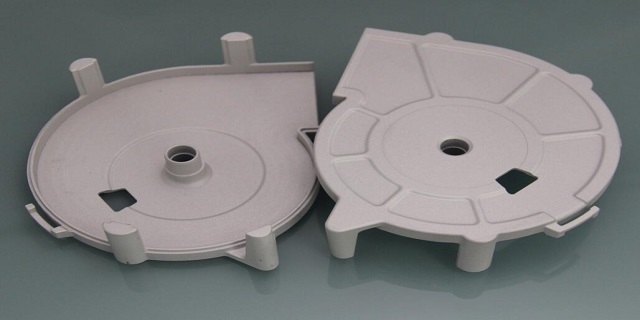

3D Printing, also known as, “Rapid Prototyping” is ideal for pre-production part verification, tradeshow and marketing samples, secondary tooling models for RTV casting, investment casting and Rapid Tooling. Many clients request our Rapid Prototyping Technologies as low volume production parts. Simulated “Like” Materials-ABS, Polyethylene, Polycarbonate, Polyamide (Nylon/GF Nylon), Carbon Fiber, Polystyrene, Somos (soft flexible material)

Prototypes with Precision, Performance and Speed to meet your needs on-demand

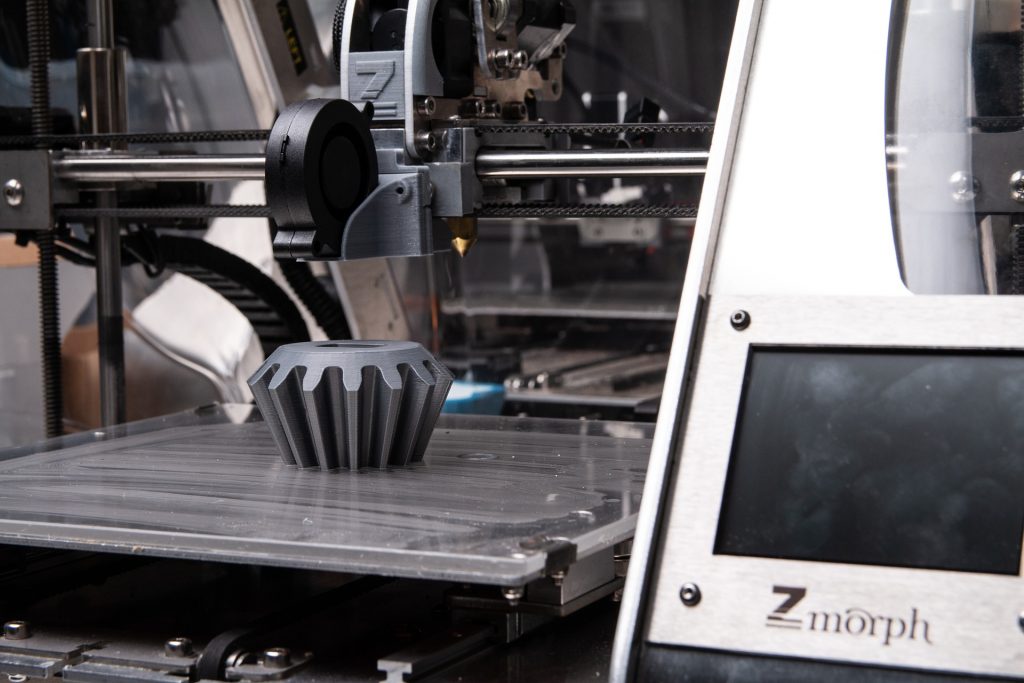

Cutting-Edge Technology: Advanced 3D printing equipment – you benefit from cutting-edge 3D Printing options to fit your needs

Custom Made Solutions: Tailored to fit your specific prototype needs – you can confirm part form, fit and functionality verification

From One Part to Multiple Parts: Whatever quantity you need, we’ll fabricate them for you on-demand

Multiple Material Options: Variety of Plastic and Metal Prototype materials – superior quality and structural integrity at affordable prices

- Need help creating CAD Designs? – Click here!

- Need 3D-Printed Prototype Parts quickly? – Click here!

- Have questions about 3D-Printed Prototype options? – Click here!

- Are your CAD files ready to go in .stl, iges or step format? – Click here!

- Have questions regarding 3D-Printed Prototype materials and finishes? – Click here!

Stereolithography (SLA)

Stereolithography (SLA) uses an ultraviolet laser that draws on the surface of liquid thermoset resin to create thousands of thin layers until final parts is formed.

Selective Laser Sintering (SLS)

Selective laser sintering (SLS) uses a CO2 laser that fuses nylon-based powder, layer by layer until final thermoplastic parts are built.

Carbon DLS

Carbon DLS uses digital light projection, oxygen permeable optics, and programmable liquid resins to produce plastic parts with excellent mechanical properties and surface finish.

PolyJet

PolyJet uses a jetting process where small droplets of liquid photopolymer are sprayed from multiple jets onto a build platform and cured in layers that form elastomeric parts.

Multi Jet Fusion (MJF)

Multi Jet Fusion selectively applies fusing and detailing agents across a bed of nylon powder, which are fused in thousands of layers by heating elements into a solid functional component.

Direct Metal Laser Sintering (DMLS)

Direct metal laser sintering (DMLS) uses a fiber laser system that draws onto a surface of atomized metal powder, welding the powder into fully dense metal parts.

Custom Finishing for 3D-Printed Parts

Looking to boost the strength, clarity, or appearance of your 3D-printed parts? Choose from microfluidic and micro-resolution materials, metal plating, secondary machining, and custom finishes like painting, clear coating, and decaling.

Advantages

Get design feedback from our experienced engineering team that has helped thousands of customers position for high quality 3D-printed parts. We will also work with you to determine optimal part orientation and materials based on your application requirements.

Across our six 3D printing technologies, we use a range of commercial-grade thermoset resins, and thermoplastic and metal powders to 3D print parts that are suitable for various part applications and industries.

If required for your parts, we offer a variety of post-process options such as heat treating, secondary machining, plating, painting, and dyeing to further enhance mechanical properties and cosmetics.

Our industry-leading tolerances and surface finish quality stems from a dedicated process engineering and quality team for each 3D printing technology. We also offer a proprietary material called Microfine™, which can build features as small as 0.0025 in.

Our facility is home to many latest 3D printing machines that produce metal and plastic parts. This means we’ll always have capacity when you need parts faster & smarter.